EPS Reusing

As we know, the purpose of recycling is not only to reduce environmental pollution but also to save resources, which means the recycled material can be used as the raw material again to make new products. EPS Recycling and Reusing are both ways to help EPS waste get its rebirth.

EPS Recycling Methods

Now several EPS recycling methods have been put into practical use, among which the machinery recycling is currently the main method adopted and proven. Machinery recycling can be divided into simple regeneration and compound regeneration.

Simple regeneration is mainly used for corner waste in production plants, but also includes disposable waste that is easy to clean and recycle. Its ingredients are relatively simple and clean, and the recycled materials can be used alone or in a certain proportion of the new materials.

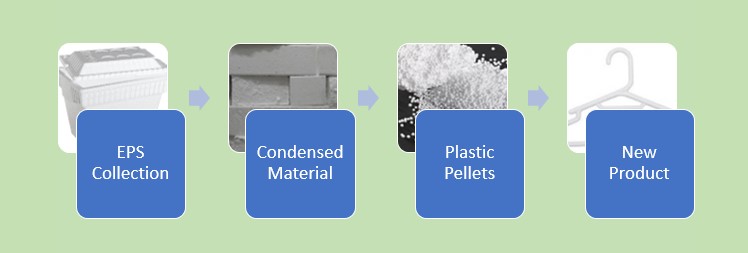

Compound regeneration is mainly used for collection through different channels after the circulation and consumption of commodities. It is characterized by many impurities, serious dirt, and difficulty in recovery. Compound regeneration requires high recovery technology and high-efficiency equipment, including collection, volume reduction, and crushing, cleaning, and separation, selection, granulation, etc.

For EPS recycling, the large volume with lightweight has always been a concern. As we know in What is EPS, EPS contains over 98% air and the volume must be reduced before recycling for saving storage and transportation fees. GREENMAX EPS Melting Machine is a polystyrene recycling machine with the volume reduction ratio of 90:1, it can crush, compact and melt the waste foam and then turn it into dense ingots. The compressed EPS ingots can be used as raw material for many new foam products.

Rebirth of EPS Waste

For EPS reusing, the most common is to use it many times with the same function, but EPS Waste can be turned into a work of art and gets its rebirth.

INTCO Recycling purchases compressed and densified EPS foam waste from around the world and transports it to a recycling plant in Malaysia for high-quality recycled granulation. The EPS pellets are reprocessed into frame strips and then assembled into photo frames, picture frames, mirror frames, and other products, which are sold again all over the world for home decoration.

The main feature of EPS Reusing lies in the recycling of renewable EPS plastics, which can be processed into various exquisite wall decoration products with INTCO Recycling’s expertise. This process of replacing wood with plastic and turning waste into treasure has broken the traditional production of wooden frames, changed the original complicated production process, as well as improved production efficiency while reducing costs, saving a lot of forest resources, and protecting nature surroundings.