EPS Recycling

EPS Recycling in Australia

In Australia about 45,000 tonnes of polystyrene is created and consumed each year. Most of this polystyrene is for long-term use, such as the insulation board used in house construction and engineering. However, about 40% (or 18000 tons per year) are recyclable after being in disposable containers or short-term packaging. The discarded polystyrene waste is a large amount of contaminants.

[*Data Source: 2014 National Plastics Recycling Survey, SRU]

The Australian Packaging Association reports that only 29.7% of the polystyrene used in packaging is recycled. Part of the problem is that, when placed in a roadside bin, small pieces of polystyrene are mixed with other recyclable waste and are considered pollutants. As a result, most recycling programs do not accept EPS bubbles for roadside recycling.

Most EPS plastic wastes are disposable and discarded in the natural world. They can neither decay and transform nor degrade and disappear on their own, resulting in serious environmental pollution and wasting valuable non-renewable resources. How to effectively recycle waste polystyrene foam has attracted widespread attention from scientific researchers in various countries.

INTCO Recycling is the leading company that provides customers with one-stop polystyrene recycling solutions. GREENMAX Polystyrene recycling machine, manufactured by INTCO Recycling, has served over 100 businesses and organizations in polystyrene related fields across Australia and New Zealand for over 10 years.

How to Recycle EPS?

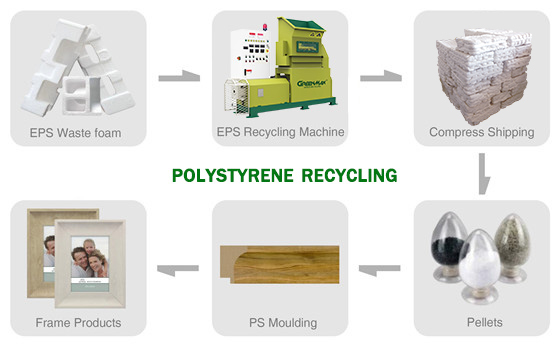

Polystyrene foam can be recycled and reused as raw materials for plastics and materials for heat generation. Turn waste into treasure – this is the most ideal way to dispose of waste foam.

Step 1: Classified Collection

Foam that is discarded during the production and processing of foams, such as scraps, are single in type, free from contamination and aging, and can be collected and disposed of separately.

Step 2: Crushing and Recycling

When the waste polystyrene is broken, it is necessary to select a suitable polystyrene recycling machine according to its nature.

For EPS recycling, a GREENMAX polystyrene melting machine can be used. The polystyrene melting machine compresses the waste EPS to a volume that is one-90th the original. The discarded EPS is converted into a foam block by compression/hot melt processing of a polystyrene melting machine.

Step 3: Resource Recycling

After screened and classified, waste polystyrene foam must undergo crushing, granulation, modification and other processes. It becomes a variety of transparent opaque particles, and then classified according to the phase, and finally becomes a recyclable material that can be reused.

The compressed or heated EPS block is granulated by INTCO Recycling, and becomes regenerated particles that can be reused, and then made into a finished photo frame, thereby increasing the recycling and utilization value of the expanded polystyrene.