Polystyrene will be Replaced in the Frozen Drink Cups of Coca-Cola Australia

Coca-Cola in Australia has announced it’s moving to 100% recycled plastic for frozen cups and lids, removing problematic polystyrene from its cold drink portfolio by the end of 2021, according to the Queensland Times. The recycled material used in the new cups and lids is to replace polystyrene, which is generally considered not to be recycled or reused.

What is Polystyrene?

Polystyrene, also known as EPS, is one of the most widely used plastic types with good thermal insulation property and shockproof performance, which made it an ideal packaging material in the catering industry for food/cups containers. In the last year, Coca-Cola has revealed for the first time it produces 3m tonnes of plastic packaging a year. Most of the plastic packaging, mainly polystyrene foam, will be discarded to landfills and then become white pollution after finishing their packaging mission.

Can Polystyrene be Recycled?

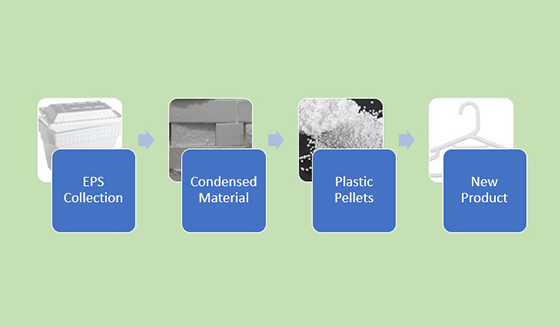

The polystyrene wastes in the landfills can neither decay and transform nor degrade and disappear on their own, resulting in serious environmental pollution and wasting valuable non-renewable resources. There has always been a misunderstanding that polystyrene waste can not be recycled and the only way to dispose of it is banning or burning. Actually, polystyrene foam can be recycled and reused as raw materials to make new products like photo frames. Turn waste into treasure – this is the most ideal way to dispose of waste polystyrene.

From the above description, polystyrene recycling sounds like a wonderful way to help polystyrene waste get its rebirth. However, polystyrene consists of 98% air and is difficult to be recycled because of its bulky volume and lightweight, even a small amount of which can quickly fill garbage bins and containers, resulting in large storage space and high transportation costs. How to recycle polystyrene packaging waste efficiently has been a chronic headache for many companies like Coca-Cola Australia. In this case, choosing a polystyrene recycling machine becomes an effective solution that is safe and environmentally friendly.

How does the Polystyrene Recycling Machine work?

The principles of various polystyrene recycling machines on the market are similar - “Polystyrene Volume Reduction”, to compact loose foam into dense blocks for transportation or storage prior to recycling. GREENMAX polystyrene melting machine is a polystyrene recycling machine equipped with the screw melting technology, specialized in reducing the volume of waste expanded polystyrene foam (EPS) by crushing, hot melting and extrusion molding.

When the polystyrene melting machine starts, throw the waste polystyrene foam into the machine hopper where it is crushed into small pieces, then drop into the screw part where the crushed foam pieces will be pushed out and then melted by heating parts. Finally, the polystyrene waste will become the hot melted ingots with a density of 90:1, greatly saving transportation and storage costs.