GREENMAX EPS recycling machine achieves EPS sustainability

Reduce, reuse, and recycle are three words we've all heard many times before. These three aspects together will achieve EPS sustainable development. Reducing the value of what we buy and reusing and repairing what we can is now a reality. But everything comes to the end of its useful life, and that's where recycling comes in. EPS recycling machine will make recycling easy.

1. Reduced usage: rethinking cargo delivery

Most goods purchased online are wrapped in EPS, usually far more than necessary. To minimize this, instead of buying one item at a time or splitting it up, pack a few more items in your shopping cart. This way you can pack them together in one large box at checkout instead of splitting up and buying many smaller packages. You can also try not buying brand new items packaged in EPS and see if you can find used, rented, loaned, or shared items to save money and take a little stress off the environment.

2. Recycling: preventing waste and reducing the need to extract and refine new raw materials

EPS is widely used in optical instruments, chemical departments and daily necessities, used to make tea trays, sugar jars, soap boxes, cigarette boxes, student rulers, combs, etc. Due to a certain degree of permeability, when made into film products, and can be a good food packaging material. There is no complete replacement for EPS substances found, so it is unrealistic to rely entirely on reduction to achieve sustainability.

There are several general ways to recycle.

* Community recycling programs

* Store return

* Professional recycling programs

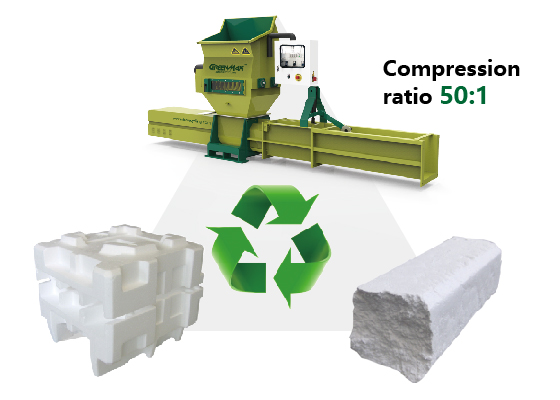

Of course, you can also do EPS recycling by yourself. GREENMAX provides professional EPS compactor will be a good helper to recycle EPS without any pollution, which can also save save waste EPS storage space and transportation costs.

GREENMAX EPS compactor first crushes the foam and then compresses it by means of physical extrusion with a screw. On the one hand, it can reduce the volume of EPS and transportation costs, on the other hand, it can provide higher density material for the later crushing process to improve the efficiency of the material.

3. Reuse: recycled EPS can be reused in home decoration, framing products, etc.

Recycled polystyrene after EPS compactor can be manufactured into high-quality recycled PS plastic particles, the purity of up to 99%, quality close to the level of pure new material, can be widely used in the insulation board industry, food packaging materials industry, clothing industry. Environmental protection frame products involve photo frames, mirror frames, picture frames, dressing mirrors, decorative paintings, and are widely used in home decoration and art framing industries in all walks of life around the world. Using recycled products protects our natural resources and avoids the alarming environmental degradation that comes with making new products from scratch.