GREENMAX Cold Compacting Technique Can Recycle EPS Waste into Value-Added Products

EPS (also called polystyrene), as you often see in fast food boxes or appliance packaging materials, has been added to the considerably larger worldwide issue of plastic waste. Annually, about 45,000 tonnes of EPS is created and consumed in Australia, a large bulk of which is thrown away after one-time use without being effectively recycled.

The reason why EPS waste is discarded into landfills and incinerated instead of being recycled is that the recycling of the great majority of plastics is not financially viable now. It is time-consuming and laborious to separate and sort them, and chemical processing and remanufacturing of plastics necessitates a considerable amount of energy input and hazardous solvents.

However, the stability and chemical durability of industrial polymers prevent plastic waste from degrading easily in landfills. Thus, it is usually burned, which generates carbon dioxide and other toxic gases. To prevent the increasing flood of polymer waste and decrease carbon dioxide emissions, plastics must be recycled or transformed into new value-added products.

At present, most roadside trash bins in Australia do not accept EPS waste from residents, which undoubtedly increases the difficulty of EPS recycling. In addition, there is also the misunderstanding that EPS is not recyclable, which leads all walks of life to prohibit the use of EPS regardless of the actual situation. In fact, EPS is 100% recyclable, and there is already a technology specifically for recycling EPS on the market, which can transform the spurned EPS foam into a new product with high added value.

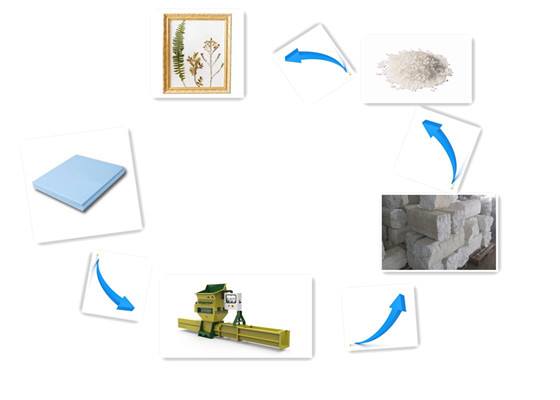

GREENMAX EPS Compactor is a professional EPS recycling machine specialized in compressing waste EPS lunch box, XPS insulation board, EPP, etc. into blocks by rotating screw pressure without heating. Equipped with the screw and automatic hydraulic system, the waste EPS foam can be pre-crushed in the storage bin of the EPS Compactor and then compacted into dense and uniform blocks with a volume reduction ratio of 50:1, greatly reducing the volume of waste EPS, therefore saving storage and transportation costs.

In this way, waste EPS will never be rejected by recycling centers because of its bulky volume, and a large amount of EPS waste can be collected and compressed with EPS Compactor. It is worth mentioning that the EPS blocks compressed by EPS Compactor will be further processed and pelletized, and made into photo frames then re-sold in the market. What a magical set of a circular economy model to turn discarded EPS into exquisite photo frame products!